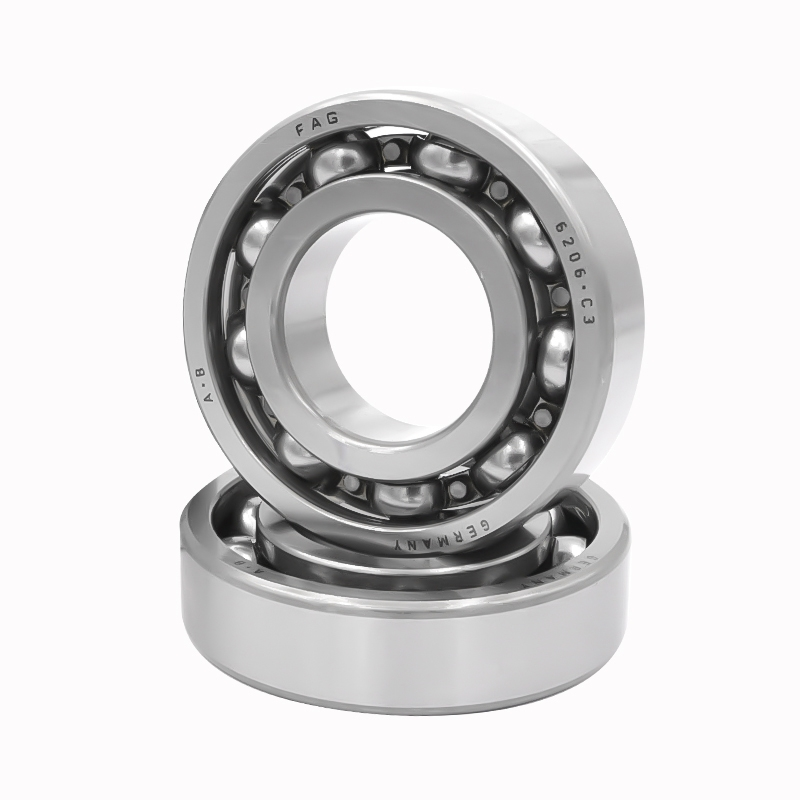

I-FAGinqubo yokukhetha Ama-lathe e-turret aqondile ahlukaniswa njengemishini yokusika yokusika.Ukuze kuhlangatshezwane nezidingo ezifanele zobuchwepheshe, ilungiselelo lokuthwala kufanele libe nezici ezifanele.Izimpawu ezibaluleke kakhulu yilezi: ■ Ikhono lejubane ■ Ukunemba kokugijima ■ Impilo yokusebenza ■ Ukuba lukhuni.

Ngokwezimo eziseduze zesakhiwo sama-bearings, izinhlelo ezihlukahlukene zokuthwala zingakhethwa.Iziphakamiso ezinikezwe ngezansi ziyinqubo yokukhetha eyisisekelo ene-IKO.Ukuze unqume uhlobo lokugcina, izilungiselelo kanye nemingcele yokusebenza, sicela uxhumane nonjiniyela wohlelo lwe-SchaefflerGroup Industrial.Isofthiwe yokubala i-BEARINX® inika amandla idizayini enezincomo nezincomo zokugcoba ngokusekelwe kumapharamitha okusebenza.Ungakwazi ukuqoqa idatha yecala usebenzisa isifanekiso esinikezwe kusithasiselo, bheka ikhasi 157. Izimo zokwakha eziseduze zinganquma ububanzi be-faceplate (ububanzi be-turret) kusukela kububanzi besayizi ye-workpiece okufanele iboshwe.Ububanzi bebhere elisekelayo eliyinhloko kufanele libe ngu-2/3 wobubanzi be-turntable.Uma ububanzi be-turntable bungaphezu kuka-7 m, ukuthwala kuvunyelwe ukusebenzisa u-50% we-diameter ye-turntable.Ijubane lingaphakathi komkhawulo wejubane, qhubeka nokukhetha ngokuya ngesivinini osifunayo.Ikhono lokuthwala isivinini liyimfuneko yokusika okuphelele futhi ngokuyinhloko kuncike ohlotsheni lokuthwala.Kwezinye izimo, ukushisa okubangelwa ukungqubuzana akunakwa, futhi ukugcoba kufanele kusetshenziselwe ukukhipha ukushisa.Lesi sidingo sibonisa indlela ukugcoba okudingekayo ngayo.

Ukunemba kwe-Workpiece Ukunemba kwe-workpiece kuncike ekusebenzeni ngokunemba kokuthwala, futhi kudinga ukunemba okuhambisanayo kwesakhiwo esizungezile sokuthwala.I-Schaeffler Group Industrial TPI 205 11 Impilo yokulinganisa Ukuze uzuze impilo eyanele yokukhathala Lh, ama-DAIDO kufanele abe nomthamo ofanele wokuthwala umthwalo, futhi igama elithi isilinganiso somthwalo esiyisisekelo sisetshenziselwa ukuveza umthamo wokuthwala umthwalo.Impilo yokulinganisa eyisisekelo yebheyili ithintwa umthwalo.Ngakolunye uhlangothi, kuthinteka usayizi wokuzala kanye nohlobo.Isici sokuphepha Ukuze kuqinisekiswe ukusebenza kahle kwe-bearing, isici sokuphepha fS 4. Asikho isici sokuphepha esengeziwe esivame ukusetshenziswa ekubalweni.Ezicelweni ezikhethekile, njengasemiyalweni yezimvume, imiyalelo yangaphakathi, izimfuneko zokunakekelwa, njll., izici zokuphepha ezifanele kufanele zisetshenziswe ngokufanele.Ukuthwala umthamo oguquguqukayo wokuthwala umthwalo Ama-Bearings amelana nemithwalo eguquguqukayo ikakhulukazi ama-bearing ajikelezayo, futhi usayizi wokuthwala unqunywa umthamo wokuthwala umthwalo oguqukayo.Usayizi webheringi engaphansi komthwalo oguquguqukayo ungahlolwa cishe ngokusebenzisa isilinganiso esiyisisekelo sokulayisha esishintshashintshayo C kanye nempilo yokulinganisa eyisisekelo L noma i-Lh.Imithwalo ehlukene Imvamisa, ithuluzi lomshini lingacubungula ama-workpiece ahlukene.Lokhu kusho ukuthi ama-bearings angase athweswe imithwalo ehlukene.Ukuze kuqinisekiswe ukusebenza kokuthwala okwamukelekayo, inqubo yokuklama yokuthwala kufanele icabangele izimo ezihlukahlukene zokulayisha.

Uma uhlelo lokuthwala luthatha ukulayisha kuqala, lungaqinisekisa ukuthi ukuthwala kunomthwalo omncane odingekayo ngaphansi kwezimo ezihlukahlukene zomthwalo.Kudingeka imithwalo encane ukuze kuqinisekiswe ukuthi ama-bearings awasheleli futhi kuncishiswe ukungqubuzana nokuguga.Ukulayisha kuqala nakho kuqinisekisa ukuqina kwesistimu yokuthwala.Umhlahlandlela onemininingwane eyengeziwe Ukusebenza kwezinhlelo zokuthwala nakho kuthintwa ukuhlanzeka nokunemba komhlangano.Ngakho-ke, ukunakwa okwengeziwe kufanele kukhokhwe kulokhu.

Isikhathi sokuthumela: Dec-13-2022