Ukufakwa kanye nezindlela zokuhlakaza zama-bearings kufanele kunqunywe ngokusho kwesakhiwo, ubukhulu kanye nezakhiwo ezihambisanayo zezingxenye ezithwala.Ukucindezela kokufaka nokuhlakazeka kufanele kusetshenziswe ngokuqondile ebusweni bokuphela kwendandatho eqinile, futhi ukucindezela akukwazi ukudluliselwa ngezakhi ezigoqayo, ngoba lokhu kuzodala ukungena endaweni yokusebenza ye-bearing, kuthinte ukusebenza okuvamile kwe ukuthwala, futhi ngisho nokulimaza ukuthwala.I-bearing cage, indandatho yokuvala, isembozo sothuli nezinye izingxenye zikhubazekile kalula, futhi ingcindezi yokufaka noma ukwehlisa i-bearing akufanele isetshenziswe kulezi zingxenye.

(1) Iringi yangaphakathi ye-bearing ifakwe ngokuqinile ku-shaft, futhi iringi yangaphandle ifakwe ngokukhululekile endlini.I-bearing ingacindezelwa ku-bearing ngomshini, bese i-shaft kanye ne-bearing ifakwa endlini.Umkhono wokuhlanganisa (ipayipi lensimbi yethusi noma elithambile) elenziwe ngezinto ezithambile zensimbi libekwe ekugcineni kwendawo yokuthwala.Ububanzi bangaphakathi bomkhono wokuhlanganisa kufanele bube bukhudlwana kunobubanzi bejenali, futhi ububanzi bangaphandle kufanele bube buncane kunobubanzi bezimbambo bobubanzi obungaphakathi bokuthwala ukugwema ukucindezela ikheji.Uma ufaka inombolo enkulu yama-bearings, isibambo singafakwa emkhonweni.

Lapho ukuthwala kufakwe, umugqa ophakathi wembobo yokuthwala kanye ne-shaft kufanele ihambisane.I-skew ye-bearing ehlobene ne-shaft akunzima nje ukuyifaka, kodwa futhi ibangela ukuhlehlisa, ukugoba kwephephabhuku ngisho nokuphuka kwendandatho yangaphakathi yokuthwala.

Ezindaweni lapho umshini wokucindezela ungekho noma ungasetshenziswa, ukuthwala kungafakwa ngomkhono womhlangano kanye nesando esincane.Amandla okushaya ngesando kufanele adluliselwe ngokulinganayo kuwo wonke umzuliswano wobuso bokugcina beringi yokuthwala, ngakho-ke ubuso bokugcina obusando bomkhono wokuhlanganisa kufanele wenziwe umumo oyindilinga.

(2) Iringi yangaphandle ye-bearing ifakwe ngokuqinile nembobo yendlu, futhi iringi yangaphakathi ifakwe ngokukhululekile ku-shaft.I-bearing ingacindezelwa endlini kuqala.Ngalesi sikhathi, ububanzi obungaphandle be-tube yokufaka kufanele bube buncane kunobubanzi bomgodi wezindlu.

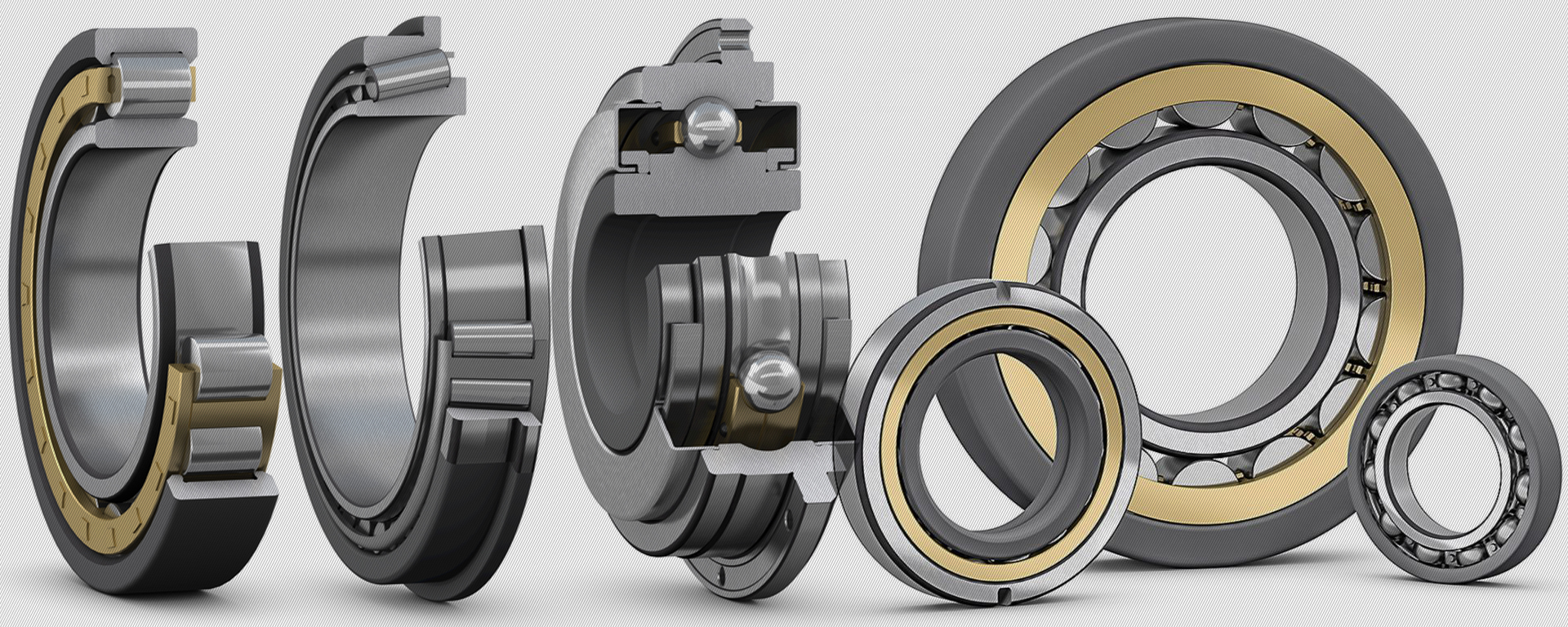

(3) Iringi yangaphakathi ye-bearing kanye ne-shaft, iringi yangaphandle kanye nembobo yendlu kufakwe ngokuqinile, futhi ubuso bokugcina bomkhono wokuhlanganisa kufanele wenziwe indandatho engakwazi ukucindezela kanyekanye ubuso bokugcina bangaphakathi nangaphandle. amaringi okuthwala, noma sebenzisa i-disc kanye nomkhono wokuhlanganisa ukwenza Ingcindezi idluliselwa emasongweni angaphakathi nangaphandle kanye kanye, ucindezela i-bearing ku-shaft futhi ungene endlini.Le ndlela yokufaka ifaneleka ngokukhethekile ukufakwa kwama-self-aligning spherical bearings.

(4) Ukufakwa kokushisisa, amandla adingekayo ukuze kufakwe i-bearing ahlobene nobukhulu be-bearing kanye nobukhulu bokuphazamiseka kokulingana.Kuma-bearings aphakathi nendawo amakhulu ngokuphazanyiswa okukhulu, indlela yokulayisha okushisayo ivame ukusetshenziswa.Faka iringi yokuthwala noma ehlukanisekayo ethangini lamafutha noma ku-heater ekhethekile bese uyishisa ngokulinganayo ibe ngu-80 ~ 100°C (akumele idlule ku-100°C) ngaphambi kokushwabana kokulingana.

Ama-Shrink-fit bearings adinga amakhono okusebenza anekhono.Lapho i-bearing ikhishwa ethangini lamafutha okushisa noma i-heater, sula ngokushesha amabala kawoyela nezinamathiselo endaweni yokuthwala ngendwangu ehlanzekile (hhayi intambo kakotini), bese uyibeka phambi kwendawo yokukhwelana ukuze uphushe. ithwala ekuhlinzeni okukodwa.endaweni ebhekene nehlombe.Phakathi nenqubo yokupholisa, kufanele ihlale iqiniswa, noma usebenzise isando esincane ukuze uthinte i-bearing ngokusebenzisa umkhono womhlangano ukuze uqinise.Uma ufaka, ukuthwala kufanele kujikelezwe kancane ukuze kuvinjwe ukufakwa ukuthi kungatsheki noma kubambeke.

Lapho indandatho yangaphandle ye-bearing kanye nembobo yezindlu ifakwe ngokuqinile, izindlu nazo zingashiswa futhi zilayishwe ekuthwaleni.Ikakhulukazi lapho isihlalo esithwalayo esenziwe ngensimbi ekhanyayo sifakwe ngokuqinile, indawo yokukhwelana ingase yonakaliswe ngenxa yokucindezela kwendandatho yangaphandle yokuthwala.Ngalesi sikhathi, isihlalo esithwalayo kufanele sishiswe.

Isikhathi sokuthumela: Mar-03-2023